Interconnection Solutions for Connectors in the Consumer Electronics Industry

Pubblicato: Apr 26, 2023

Consumer Electronics

Condividere:

Pubblicato: Apr 26, 2023

Consumer Electronics

Condividere:

With 5G, the Internet of Things, artificial intelligence, virtual reality, new display, and other emerging technologies, and the integration of consumer electronics products, consumer electronics products accelerate the renewal, giving rise to new product forms, driving the consumer electronics industry to maintain growth momentum, is expected to reach 1.11 trillion U.S. dollars in the global consumer electronics industry market size by 2023.

Consumer Electronics Connectors

Consumer electronics is the third largest downstream application area of connectors; in the downstream industry, product technology enhancements, and consumer upgrade demand under the multiple stimuli, the consumer electronics connector industry will also grow steadily.

According to Bishop & Associates, the global sales revenue of consumer electronics connectors in 2019 was $3,109 million. The market size of consumer electronics connectors is expected to be $3,926 million in 2025, at a CAGR of 4%.

The regional sales revenue of consumer electronics connectors in China market was $1.098 billion in 2019 and is expected to reach $1.215 billion in 2025.

Wire-to-Board Connectors

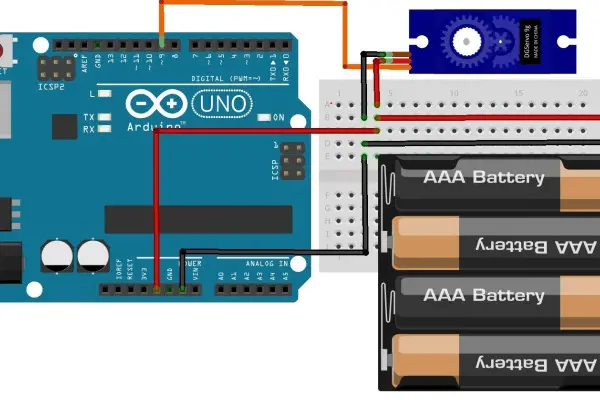

Connectors in consumer electronics are widely used, and wire-to-board connectors are among the very common types of products; the difference between wire-to-wire connectors and board-to-board connectors is that the connector ends are connected to different types of products, wire-to-board connectors are connected to the wire and board connectors, the function is mainly to transmit current and signals.

Due to the many types of products in the field of consumer electronics, the performance of wire-to-board connectors and functional diversity and differentiation requirements are obvious, requiring manufacturers to design and manufacture for different application needs.

What's more, 3C electronic miniaturization, functional integration, and low power consumption have become the current trend, but wire-to-board connector material selection, product design, and size still need to continue to improve.

New Trends and New Technologies

The main drivers in the design of consumer electronics connectors are the need to interconnect and transmit high-speed data signals, smaller sizes, lighter weights, etc.

These challenges can be met by new plating technologies, improved coupling options to ensure a secure connection between the two connectors, smaller compact designs, sealing levels, etc.

Rugged connectors are usually made of nickel-plated brass. However, many applications require aluminum and stainless steel or even composite plastics.

Nickel/chrome-plated brass connectors are highly wear-resistant and offer a longer service life than many other materials. Zinc-nickel-based plating can provide high electrical conductivity and signal stability.

Plastic may be a good choice for use in scenarios where the wear rate is not high, but full testing may be required to confirm durability.

Lightweighting and Miniaturization

With the development of electronics technology, components are getting smaller, and circuit density is increasing, prompting connectors to increasingly miniaturize, high density, high-speed transmission, and other directions to complete the breakthrough; miniaturization has become one of the most powerful design trends.

Although the miniature connector is a good form of packaging, sometimes only a few designs can transmit power and signal at the same time. If the pin size is too small, it does not meet the required power, or the signal is more susceptible to interference. As connector packages become smaller and smaller, the voltage withstood is also becoming smaller, requiring smaller connector center spacing and higher technology.

When considering cable assemblies and the impact of data speed and miniaturization requirements, the choice of connectors may become more complex. The factors associated with supporting the full functionality of the connector and the strength requirements are important, and custom connectors can meet these requirements.

Integration and Efficiency

The integrated design of wire-to-board connectors not only enables the compression of contacts but also enhances the efficiency and area of the connection to the partially gold-plated substrate by compressing the contacts and increasing flexibility. As a result, it is widely used in refined industrial fields such as printers, mobile devices, and GPS.

The use of temperature and heat-resistant plastic housing enables a wider range of use. The all-in-one simple wire-to-board connector has many dimples in the contact area to prevent damage caused by accidental dislodgement and also further reduces the thickness of solder paste for maximum precision.

The simple design makes the integrated wire-to-board connector easier to use, enabling an ideal environment for low wear, long life, and high refinement.

Interconnect Technology Solutions

As technology upgrades, the market demand for high-speed connector applications continues to grow. The use of connectors with high design levels allows for safer, more reliable, and more efficient equipment operation.

As a supplier committed to providing a variety of solutions for the connectivity industry, focusing on solving a variety of interconnection needs, Electronic Valley's broad product portfolio and high-performance interconnection expertise make it possible to complete a highly reliable signal connection within the overall device, can meet the application requirements of different scenarios, helping customers to be able to quickly select the right connector to respond to better product design.

Application Scenario Introduction and Case Show

LCD monitor motherboard

The monitor is an indispensable output device for PC. For the application scenario of LCD monitor motherboard, Electronic Valley is equipped with a series of relevant and applicable connectors, such as HDMI, D-SUB, DC JACK and wire-to-board connector series, and other overall solutions; its associated products have high-speed transmission, anti-dislodging, does not occupy space and other advantages of performance, suitable for use in limited space.

Consiglia prodotti

Related Solutions

-

![NXP Introduces High-Power Wireless Charging Solution for Laptops and 2-In-1 Tablets]()

NXP Introduces High-Power Wireless Charg...

NXP Semiconductors announced the first high-power wireless charging solution for notebooks and 2-in-...

Apr 28, 2023 Elettronica di consumo -

![Multifunctional Street Light Automatic Control Circuit Solution]()

Multifunctional Street Light Automatic C...

The street light automatic controller is suitable for the automatic control of street lights in resi...

Apr 26, 2023 Elettronica di consumo -

![How Can IoT Solution Providers Build a Secure IoT System at Different levels?]()

How Can IoT Solution Providers Build a S...

The Internet of Things (IoT) has been attracting a lot of attention in the industry for its security...

Apr 25, 2023 Elettronica di consumo -

![ADI Proposes a Solution for Servo Motor Control]()

ADI Proposes a Solution for Servo Motor ...

For motor control solutions, ADI offers a comprehensive portfolio of products, including analog-to-d...

Apr 25, 2023 Elettronica di consumo -

![IoT Transforms and Adds Value to Consumer Electronics Industry]()

IoT Transforms and Adds Value to Consume...

The Internet of Things (IoT) is taking consumer electronics to another level and could lead to the n...

Apr 26, 2023 Elettronica di consumo -

![Texas Instruments Programmable Logic and Automation Controller (PLC/PAC) Solutions]()

Texas Instruments Programmable Logic and...

Programmable logic controllers (PLCs) and programmable automation controllers (PACs) process and con...

Apr 26, 2023 Elettronica di consumo

Tempo di aggiornamento: Apr 26, 2023 Elettronica di consumo

Tempo di aggiornamento: Apr 26, 2023 Elettronica di consumo